Freight's Barn Construction

The Stabilization of Steel

When we first discovered the depot, three fifths of the trusses were either broken or no longer holding the roof up. The east wall was 2 ½ inches off plumb. When a structural engineer stepped on site his words were, “How the hell is this thing still standing?” We reinforced the entire structure with $140,000 worth of steel to keep it from falling over. The depot was ready to fall over when it was purchased in May 2017. 3 of the 5 trusses were no longer functional. The solution? To sandwich existing timbers with steel. This allowed the original framing to remain exposed while bringing the walls close back to plumb. Both East and west walls were trying to fall outward and were 2.5″ to 3″ off plumb. Cam straps were used to pull the building back in line as steel was inserted.

In order to shore up the existing trusses, the roof had to be slit open above each one and steel dropped in through the roof. Each original roofing slat was removed, numbered, saved, and replaced in exactly the same position to maintain historic integrity.

Preservation of Historic Shed

To the West of the courtyard, the original shed was used to store Lye. A neighbor remembers coming to the shed as a child to get ingredients for Ludefisk. To the East, the old lumber stand holds salvaged materials from the renovation. We are hoping it will one day become a bandstand shell.

Leadville is the highest incorporated city in North America. That means it gets pretty cold up here! To make this building a year round space, each stud space has been scraped, dusted, vacuumed, filled with batten insulation, covered with plywood, wrapped in moisture barrier, covered with rigid insulation, furred, and new siding returned to the outside. There are over 700 stud spaces, none of which are the same shape or square. That’s a lot of custom work!

Using the rough edge of new siding brings the texture and feel of the original siding while adding material integrity.

Soundproofing with Tectum

There were 572 stud spaces to reckon with. Each stud space was scraped, swept, and vacuumed. We added three layers of insulation to every stud space to create soundproofing, with our neighbor’s in mind. To conceal the insulation, we used Tectum, which has the texture of dried spaghetti.

A True Foundation

You might expect the foundation of such an old building to have been trashed by weather and time. Many buildings in Leadville have a mud sil foundation, but not this one, which is part of why it’s held. The depot is actually sitting on top of 120 tree trunk logs. They were likely logged locally and covered in creosote to help preserve them. They aren’t dug in, but rest on the ground. On top of them there are 41 foot, 12 x 12 timbers, then you have 4 x 12 joists. There’s lot of air flow throughout the entire foundation. We were thrilled when we checked to find foundation was so sturdy, the walls and trusses were what really needed work.

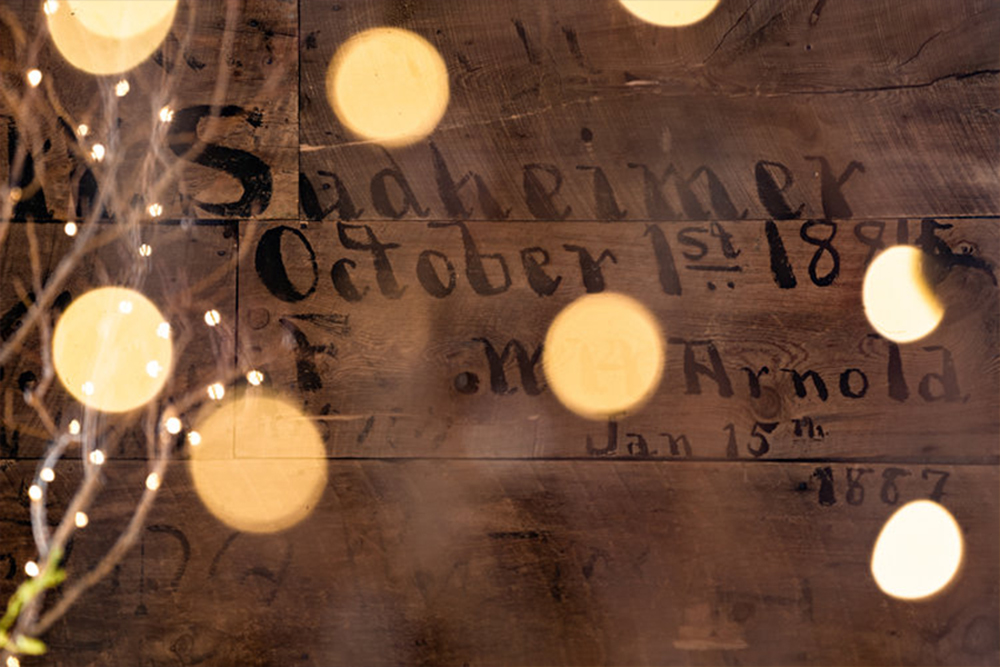

Bumperboard Resurrection

A feature of many freight depots are bumperboards protecting the walls. These boards are built to withstand collisions. You won’t see them in a passenger depot. We took down the bumperboards and hand scrubbed each one. We liberated 135 years of dirt and grime, revealing graffitied names of those who had passed through over the ages. This is actually how we discovered the earliest date of the building. Leadville’s county record suffered from a devastating fire in 1888, which is why many buildings in town have this stock date of origin. The Sanborn Surveys covering the history of the West can be another way to date a building. The FREIGHT depot doesn’t come up in the surveys until the 1890s. However, in cleaning the bumperboards, we found an earlier date for the building scrawled in cursive penmanship: Oct 1, 1884.

We uncovered the original color of the building from underneath a 20th Century addition. Here you can see how the exposure of 10,200′ and heavy winters faded the original purple of the depot into a barn red. We’re bringing the purple back!

Where materials could be salvaged, they were! The East dock has an extensive eve (seen here) with gorgeous brackets. This saved much of the siding and anything that needed replacing received original materials back in it’s place.

Restoration of Original Doors and Windows

All of the doors and windows are original and were restored in Denver. Glass is an inert liquid, so over time it can have a melted look. If you look closely, there’s a slight warped sheen to some of the windows, expressing authentic age.

Siding in the Conductor’s Office

The siding in our office is a metaphor for the building itself. It’s the continuity of old meets new. The original siding is on one half of the room and it had to be custom matched to fit together with the new siding perfectly. It’s an example of how the modern and historic can meet in balance. We run our operations out of the same office where the conductor once went about his business, reading the newspaper, and checking documents of inventory, the train huffing by out the window.

Preservation of the Original Floors

The history of weight is in the wood planked floors. It’s one of our favorite features of the building. Imagine the crates of ore, eggs, clothing, coal, flour, and livestock passing through on any given late 1800s afternoon. The building has lived through three centuries of traffic and you can see there’s the wear in the floor near the doors, where merchandise was herded in, ticketed, and sent on its way.